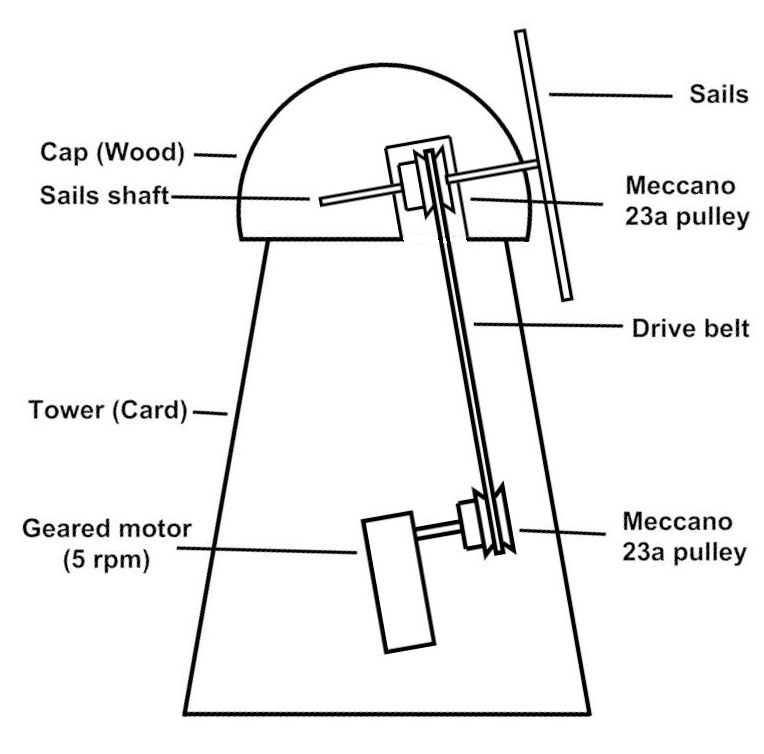

When deciding what to incorporate on to “Foxwood Park”, our model tramway and narrow gauge railway, a windmill was high on the list after the town, tramway and railway buildings.

However when we started to look at ready motorised model windmills we found that that although there were a number available, there did not appear to be a model of a traditional English tower mill.

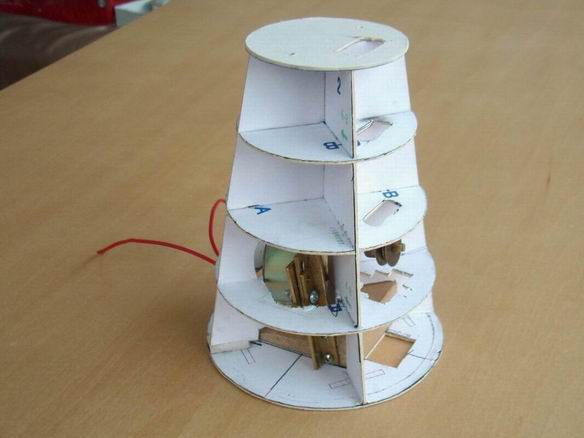

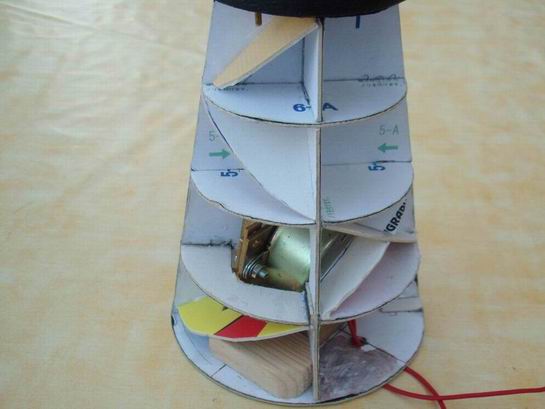

As we had not built a tapered tower, we looked to the Internet for help where a Japanese website was found which had plans for a Dutch tower mill.

These plans were ideal for building the tower and as downloaded were the correct size for a 00 scale model but after the windmill was built this website disappeared.